Infrastructure That Drives GeeGee Quality

Equipped for Excellence. Engineered for Output.

At GeeGee Garments, our infrastructure is the foundation of our promise—delivering unmatched quality at scale.

Our facility is equipped with advanced machinery including computerized Juki single and double needle machines, feed of the arm systems, overlock units, fusing machines, cutting-edge cutting technology, and finishing equipment.

Total Customers

Packaging & Dispatch

Online Order Pickup

Real Stories, Real Satisfaction: Hear from Our Customers

Our High quality Garment manufacturing facilities

We have established a state-of-the-art 60,000 sq. ft. garment factory in Pallipalayam, Erode, Tamil Nadu, to meet growing customer demands. Our facility is equipped with hi-tech, fully automated machinery, ensuring precision and efficiency in production. Additionally, we provide well-organized hostel facilities for both boys and girls, ensuring a comfortable stay for our workforce.

Our advanced infrastructure is designed to enhance productivity while maintaining the highest quality standards. With cutting-edge machinery and streamlined processes, we ensure efficient manufacturing that meets global benchmarks.

Manufacturing

Our dedicated team ensure high quality and craftsmanship standard remains consistent whether order quantity is 1,000 or 1,00,000 pieces.

MOQ

Minimum order quantity is 1000 pieces per colour, per style. A large order quantity allows higher efficiency at a reduced manufacturing cost.

Process & Quality

A strict regime of internal audits, critical process check, 3rd party testing on fabric/accessories/garments and Pre-final Inspection done prior to shipment.

HR Policy

We follow a strict Code of Conduct (CoC) imbedded in our HR Policy – a guideline to follow our company’s rules and regulations and value every individual.

Our Machineries Details

State-of-the-Art Machinery at GeeGee Garments

At GeeGee Garments, we operate with a large fleet of advanced machinery, ensuring superior quality and high-volume production.

238+ High-Tech Machines

Equipped with Juki, Brother, and Siruba units for precision, efficiency, and reliability.

Advanced Sewing & Stitching

Includes computerized single and double needle machines for high-quality production.

Cutting-Edge Cutting Machines

Features straight knife, edge cutter, and end cutter machines for accuracy.

Automation & Energy Efficiency

Integrated with electric feed length control and energy-saving motors.

Superior Finishing Equipment

Steam irons with vacuum tables and fusing machines ensure flawless garment quality.

Optimized Workflow

A well-structured setup enhances productivity while maintaining international standards.

Special Machines

Our Hi-Tech Special Machineries

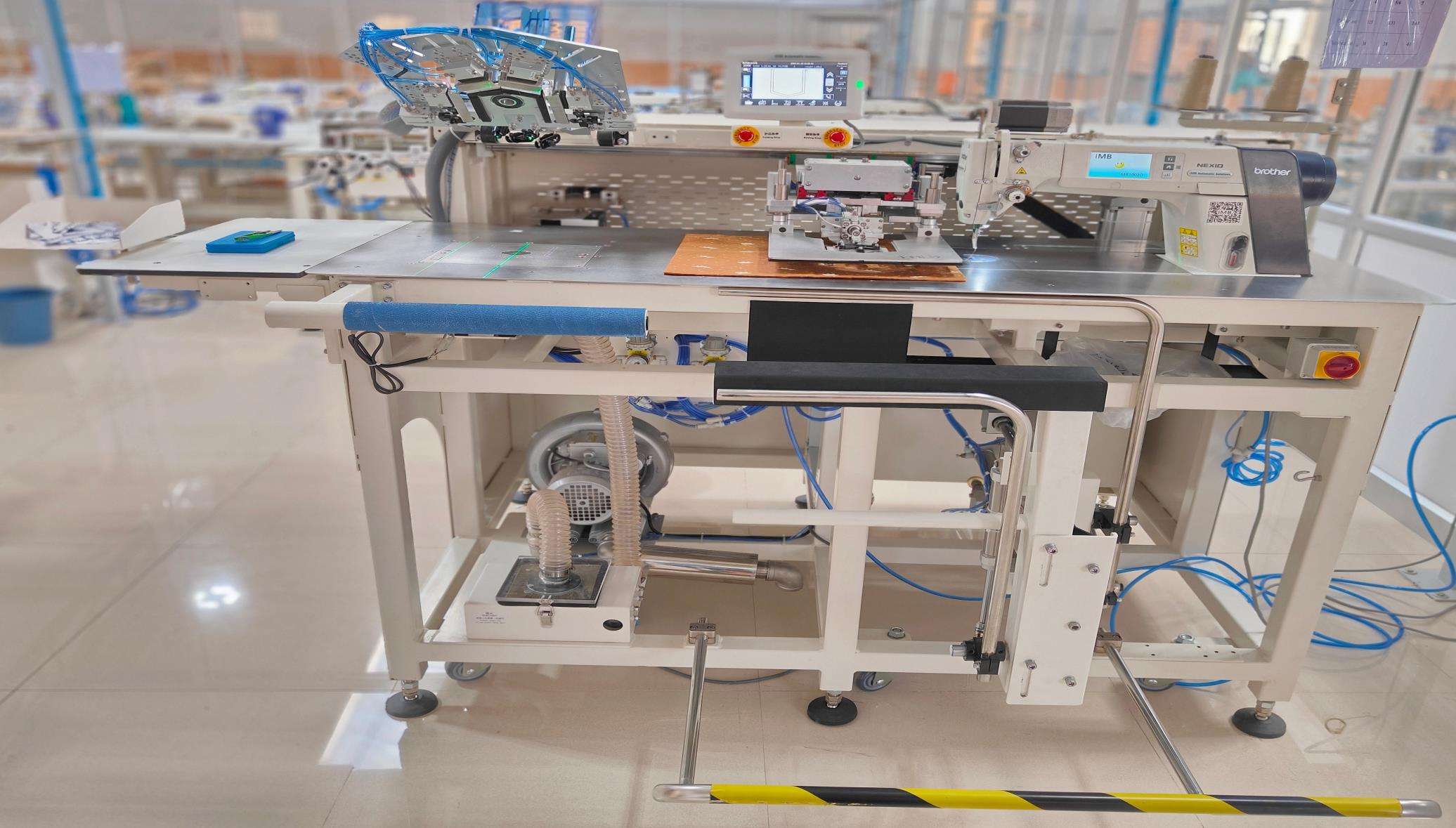

Automatic Pocket attach Machine

The Automatic Pocket Attach Machine enhances efficiency by precisely stitching pockets with speed and accuracy. Designed for high-volume production, it ensures uniform stitching, reduces manual effort, and improves overall productivity.

Automatic Sleeve Placket attach Machine

The Automatic Sleeve Placket Attach Machine is designed for precision and efficiency in attaching sleeve plackets with uniform stitching. This advanced machine enhances productivity by reducing manual labor while ensuring consistent placement and finishing.

Automatic Button Hole Sewer Machine

The Automatic Button Hole Sewer Machine is designed for high-speed, precise buttonhole stitching, ensuring uniform size and clean finishing. With advanced automation, it enhances efficiency, reduces manual intervention, and maintains consistent quality across garments.

Automatic Button Sewer Machine

The Automatic Button Sewer Machine is engineered for fast and precise button stitching, ensuring strong and uniform attachment. With advanced automation, it reduces manual effort, increases productivity, and maintains consistent quality.

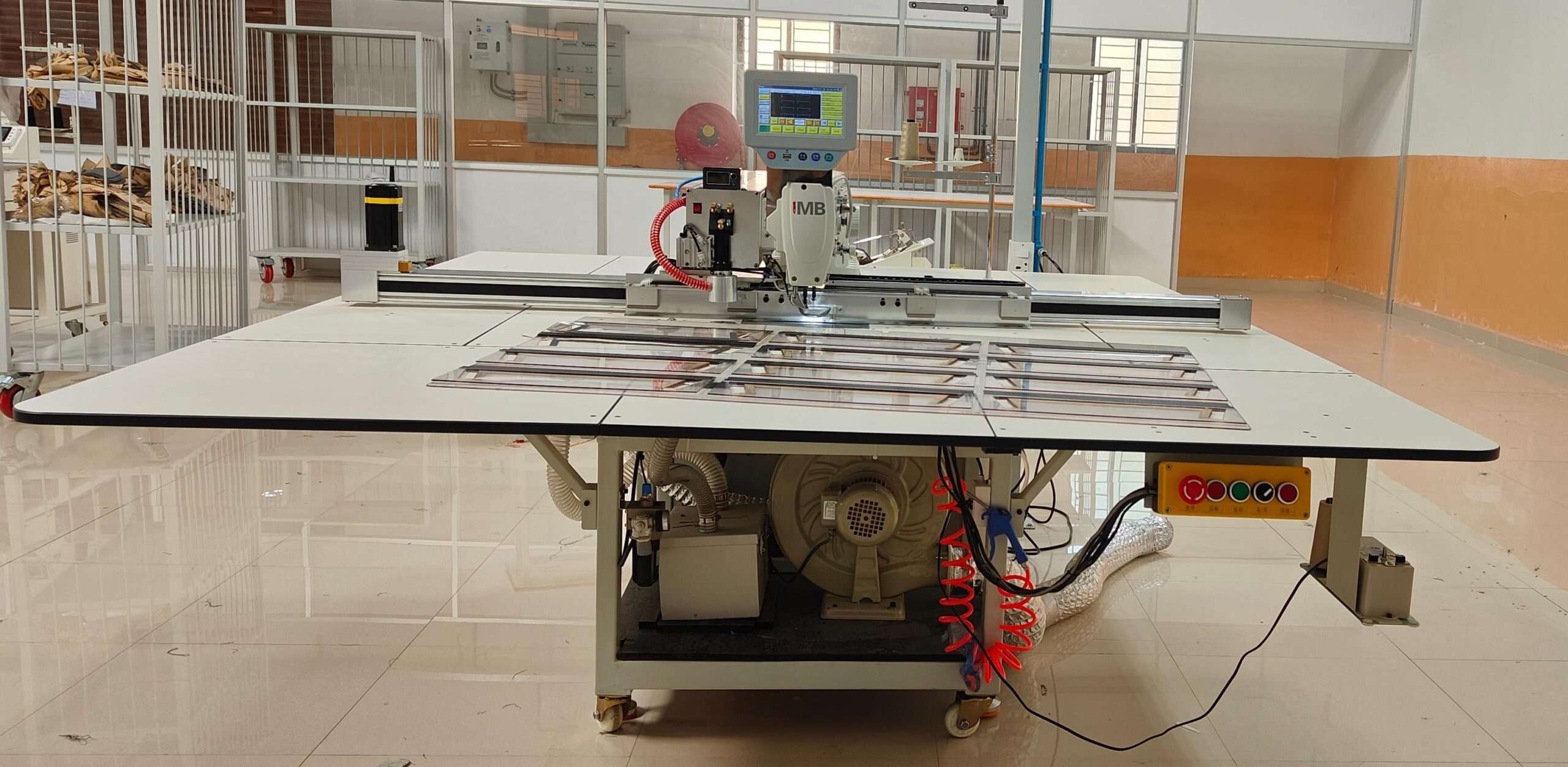

Automatic Collar and Cuff attach Machine

The Automatic Collar and Cuff Attach Machine ensures precise and efficient stitching of collars and cuffs with uniform alignment and strong seams. Designed for high-speed production, it reduces manual labor while maintaining consistent quality.

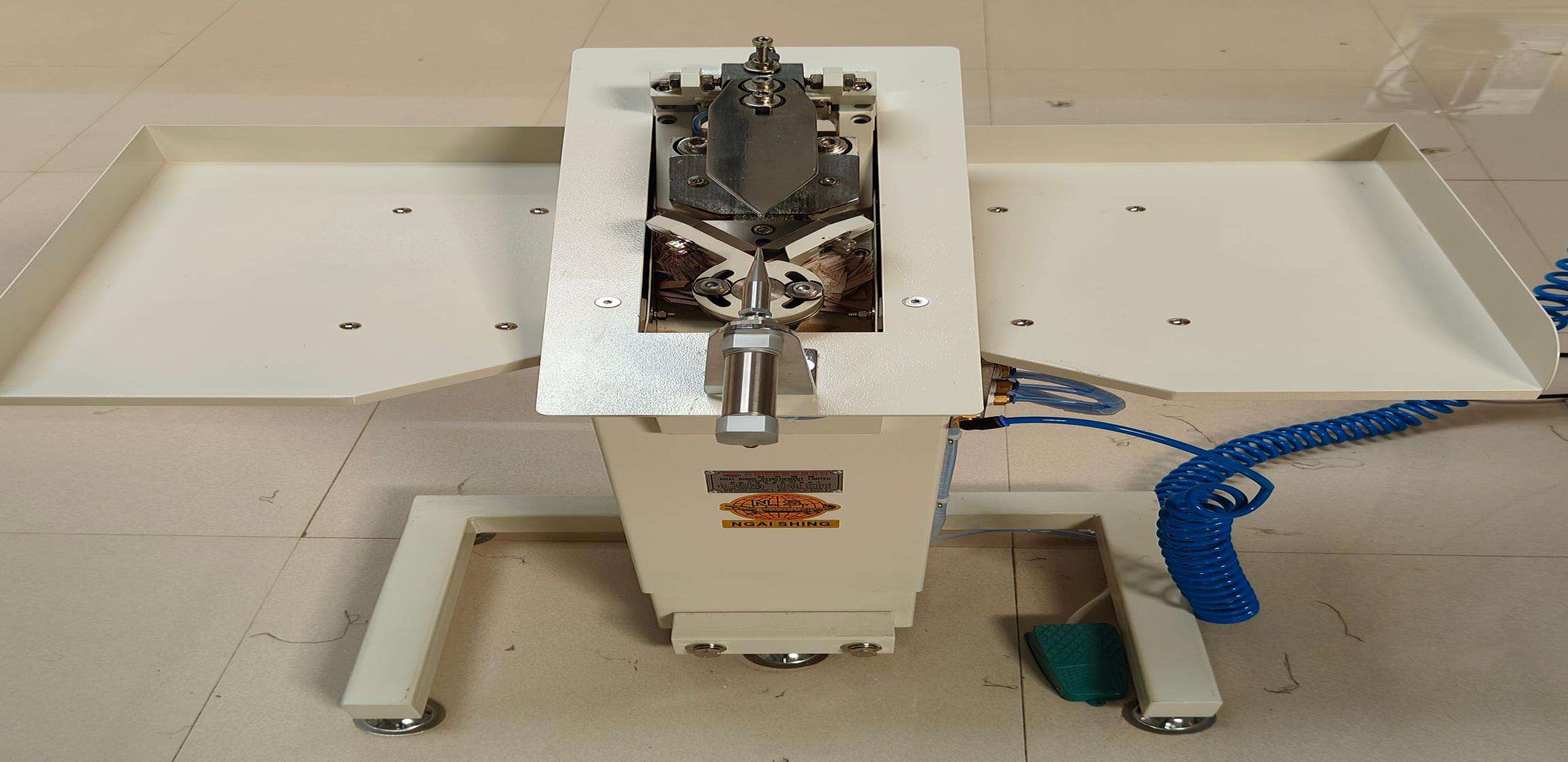

Collar Trimming and Turning Machine

The Collar Trimming and Turning Machine is designed to precisely trim and turn collars, ensuring clean edges and perfect shape. This high-speed machine enhances efficiency by reducing manual effort while maintaining consistent quality.